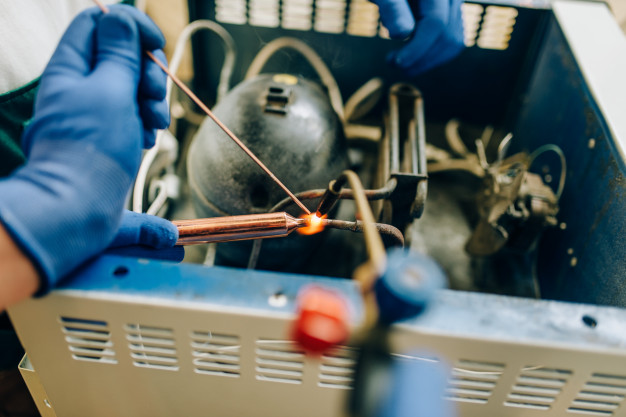

- Maintenance & Repair

Cascade is your next-door support team providing whole range of services for environmental test chamber. Our maintenance & repair support keep your test chamber away from downtime and unplanned maintenance cost.

- Upgrades & Retrofits

To adapt to the changing testing needs and validation requirement, every test chamber require upgrades. Cascade provide end to end system upgrades for all systems, sub-systems and structure.

- Calibration & Validation

- Parts

- Company

- Contact Us